How Recycled Paper Products Are Made: Step-by-Step Explained

The numbers might surprise you - paper and paperboard waste makes up 23.1% of total municipal solid waste. Paper recycling facilities processed an incredible 67.4 million tons of waste material in 2018.

The recycling success story gets better. About 46 million tons - or 68.2% - of paper waste found new life through recycling[-4]. This rate tops the charts among all materials in municipal solid waste. Cardboard's story is even more impressive, with recycling rates soaring to 91.4% in 2021.

Paper recycling does more than just keep waste out of landfills - it protects our valuable resources. A single ton of recycled paper saves 7,000 gallons of water and generates enough energy to power an average home for six months. These benefits make understanding the recycling process a vital part of environmental conservation.

This piece will guide you through each step of the paper recycling process, with special attention to India's methods. You'll discover the journey your discarded papers take - from local kabadiwalas collecting them to their transformation into new products without bleach. Let's explore how everyday paper waste becomes something useful again.

What Happens to Your Paper After You Throw It Away

Paper recycling starts well before it reaches any factory. Your discarded newspapers, notebooks, and cardboard boxes begin their trip through a complex waste management system that works differently in Indian cities.

How paper is collected in Indian cities

Most Indian cities rely on municipal corporations to handle formal waste collection. These corporations provide separate bins for biodegradable and inert waste. The current collection system faces many challenges. Major roads and markets get daily sweeping, but residential streets see cleaners only twice a week or less. Data shows that 75-80% of total municipal waste gets collected. Only 22-28% of this collected waste gets processed and treated. Many households dump their garbage in open spaces and water bodies, especially in underserved communities.

Role of kabadiwalas and informal sector

India's vast informal waste sector helps fill vital gaps in the system. Kabadiwalas serve as the first link in the recycling chain. These traditional waste collectors gather waste directly from homes and businesses. They sort and separate materials like paper, plastic, metal, and glass carefully before selling them to recycling factories. This sector provides jobs to over 2 million people from marginalized communities. It generates an estimated ₹1096.95 billion annually.

The digital world is revolutionizing this traditional system. Bhopal's residents can now schedule waste pickup through apps like The Kabadiwala and get paid for their recyclables. This program has 70 public drop-off points and partners with the Municipal Corporation to collect used packaging from sorting centers.

Why segregation at source matters

Waste segregation at home stands as the most vital principle in waste management. Paper waste mixed with food waste or non-recyclable materials ruins entire batches. This makes recycling hard or impossible. Useful materials end up in landfills instead of being reused.

The 2016 Solid Waste Management Rules require source segregation into three categories: biodegradable, non-biodegradable, and hazardous waste. Different cities show varied results. Some smaller towns have reached 100% segregation. Larger cities like Bengaluru and Pune achieve only about 50% source segregation. Cities like Indore and Mysore show impressive results with 90% and 95% segregation rates.

Properly segregated paper waste flows into an efficient recycling stream that saves resources and helps the environment.

Sorting and Preparing Paper for Recycling

Paper recycling success depends on proper sorting that turns waste paper into raw material instead of trash. The process requires careful classification of paper based on quality and fiber content.

Types of recyclable and non-recyclable paper

You can recycle most paper products including newspapers, magazines, catalogs, copy paper, printer paper, and envelopes - even ones with windows. Clean cardboard boxes, packaging materials, phone books and directories work great too.

Some paper products just don't work for recycling. Used tissues, napkins, and paper towels can't be recycled because they're made from recycled paper with fibers that are too short. BPA in thermal paper receipts makes them impossible to break down. The same goes for sticky notes and adhesive papers. Milk or juice cartons with plastic/aluminum lining and shredded paper with tiny fibers also end up as waste.

Manual vs machine sorting in India

India's paper sorting combines old-school manual methods with new tech solutions. Workers in many areas still separate different grades of paper and remove contaminants by hand.

Machine sorting keeps getting more popular though. The TARA PaperMek technology works perfectly for Indian conditions and provides affordable recycling solutions for offices and institutions. These machines come in three sizes - the TARA PaperMek-V handles 25-30 kg each day. You'll find these systems in more than 500 Delhi-NCR schools, government offices, and army units, showing how mechanical sorting is taking off.

Challenges with food-stained and coated paper

Food contamination makes paper recycling tough. The rules say surface stains are fine, but any stuck-on food means that paper heads straight to the trash. Pizza boxes tell this story well - they should be recyclable, but grease usually sends them to composting instead.

Coated papers create their own headaches. Paper cups, food containers, and tetra packs usually have plastic or aluminum layers that mess up recycling. You need special equipment to separate these materials. Polyethylene-coated paperboard used in cups and aseptic packaging causes real problems because fibers get stuck in the plastic film, which means we recover less material.

The good news? Most paper waste can make it into recycling if we sort and prepare it right.

The Paper Recycling Process Step by Step

Image Source: Holmen

Paper waste starts an amazing trip when it reaches a recycling facility. Indian recycling facilities use traditional methods with modern updates and avoid harsh chemicals like bleach.

1. Pulping without bleach in India

Breaking down paper into fibers marks the first step. Most Indian facilities prefer mechanical pulping over chemical methods. The process happens in large vats called pulpers where workers mix waste paper with water. This creates a slurry that breaks down fibers naturally without harsh chemicals. The temperature stays between 45-55°C. Paper makers in India let the material soak longer to separate fibers naturally, which keeps them strong and high quality.

2. Removing ink and contaminants

The deinking process uses either flotation or washing to clean the paper. Air blown into the pulp mixture creates bubbles during flotation. A special collector agent makes ink stick to these bubbles, creating a froth that floats up for easy removal. The washing method uses dispersants to clean printing inks as the pulp slurry loses water. This method removes tiny particles smaller than 30 μm and protects the cellulose fiber quality.

3. Forming sheets from pulp

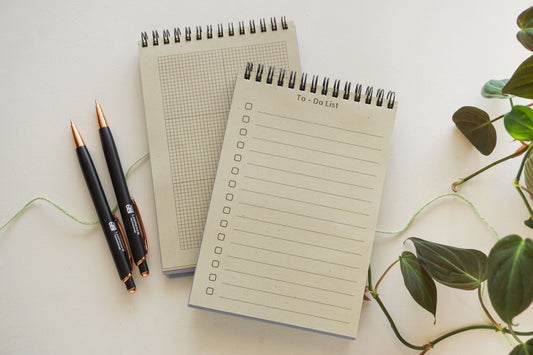

Clean pulp moves to sheet formation on screens. Traditional Indian artisans make handmade paper using two methods. The "lifting method" works best for thick papers - artisans pour pulp onto a mold, clamp it between wooden frames, then dip it in water. They use the "dipping method" for fine papers by putting the mold into diluted pulp.

4. Drying and pressing the sheets

A hydraulic press squeezes out extra water from new sheets. The paper still holds 50-65% moisture and needs thorough drying. Many Indian facilities still use the sun - hanging sheets outside or laying them on screens. Coloured paper needs shade-drying to prevent fading. Modern facilities speed up the process with heated cylinders.

5. Quality checks before reuse

The final stage involves careful inspection of paper quality, strength, and consistency. Workers carefully remove any remaining dirt with special tools. Most facilities coat the paper with starch to boost quality and stop ink from spreading. The paper then goes through calendaring - pressed between metal plates and spring-loaded rollers. This creates smooth, glossy sheets ready for cutting to size.

What Recycled Paper Becomes in India

Recycled paper fibres in India get a new lease of life as everyday products. Let's look at how waste paper becomes useful items through new ideas and traditional craftsmanship.

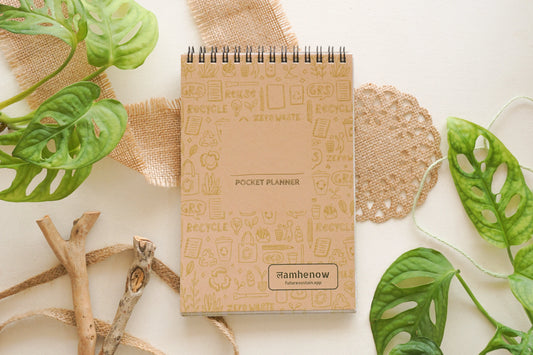

Notebooks, packaging, and tissue paper

Most recycled paper ends up as notebooks, packaging materials, and tissue products. Companies like Green-O-Tech India make all kinds of stationery from 100% recycled paper. You'll find note pads, conference folders, spiral books, and executive diaries that meet international quality standards. Paper recycling has picked up steam, and India's paper recycling rate now touches nearly 30% of total paper use. This green packaging saves resources in a big way. For every ton of recycled paper, we save 17 mature trees, 26,000 litres of water, and 4,000 kWh of energy.

Tissue paper is another major product line. These items include kitchen towels, facial tissues, bathroom tissue, and paper napkins. The market shows promise as tissue paper products keep seeing strong double-digit growth in India.

Use in handmade paper industries

India's handmade paper sector brings something special to the recycling ecosystem. Right now, 310 handmade paper units produce about 7,000 tons each year. These units create goods worth INR 210.95 million and employ 5,300 people. Unlike factory production, handmade paper only uses non-forest materials like cotton rags, waste paper, and waste kraft.

TARA stands out by creating over 100 types of handmade paper from waste paper, rags, and farm leftovers. They make specialty products for industry needs, including high-quality filter paper that car manufacturers use.

How recycled paper supports local businesses

The recycled paper industry creates jobs and opportunities across India. Green-O-Tech helps over 500 clients turn their waste into wealth. Many companies now include recycled stationery in their Corporate Social Responsibility plans.

This industry helps marginalized communities find work. Take TARA's handmade paper unit near Delhi - it employs 35 women and 7 men. Women run key manufacturing operations here. Indian handmade paper products are a hit overseas too, especially in the USA, Germany, Europe, and Australia.

The paper recycling industry leads the way in building a circular economy in India. It shows how green business models can work.

Conclusion

The Circular Journey of Paper in India

Paper recycling stands as one of India's greatest sustainability success stories. This piece follows the remarkable trip of discarded paper—from collection by kabadiwalas to its new life as useful products.

Without doubt, India's traditional recycling methods give us huge environmental advantages. Our approach skips harsh chemicals like bleach and saves resources, unlike many Western processes. Each ton of paper recycled saves 17 mature trees, 26,000 liters of water, and 4,000 kWh of energy. These numbers matter a lot to our growing nation.

The social effects run deep too. This industry creates jobs for millions in the recycling chain—from waste collectors to artists who make handmade paper products. Women find good work in manufacturing units where they run key production tasks.

Digital platforms now connect waste producers with recyclers, showing how old ways and new tech work together smoothly. All the same, we face hurdles, especially when you have waste sorting at source. Cities like Indore and Mysore show great results with over 90% segregation rates, but many big cities still can't get their waste management right.

Your actions at home make a real difference. The way you sort paper from other waste decides if it gets recycled or ends up in landfills.

India's paper recycling success proves we can build business models that protect nature and boost growth at once. We all play a part—buyers, companies, and government officials can help this system grow by making smart choices, sorting waste properly, and seeing gold where others see garbage.

We have a long way to go, but we can build on this progress. Our skill at turning old paper into new products shows that the path to sustainability often lies in seeing new possibilities rather than throwing things away.

FAQs

Q1. How does the paper recycling process work in India? The process typically involves collecting waste paper, sorting it, pulping without bleach, removing ink and contaminants, forming sheets from the pulp, drying and pressing the sheets, and performing quality checks. This method often combines traditional techniques with modern adaptations, emphasizing resource conservation.

Q2. What types of paper can be recycled? Most paper products can be recycled, including newspapers, magazines, copy paper, envelopes, and cardboard boxes. However, tissues, napkins, thermal paper receipts, sticky notes, and milk or juice cartons with plastic/aluminum lining are generally not recyclable due to contamination or composition issues.

Q3. How does paper recycling benefit the environment? Paper recycling significantly reduces waste in landfills and conserves resources. Recycling one ton of paper saves approximately 17 mature trees, 26,000 liters of water, and enough energy to power an average home for up to six months.

Q4. What products are made from recycled paper in India? Recycled paper in India is transformed into various products, including notebooks, packaging materials, tissue paper, and handmade paper goods. These range from stationery items and eco-friendly packaging to specialty products like high-quality filter paper for automotive manufacturers.

Q5. How does the paper recycling industry impact local communities in India? The paper recycling industry creates significant economic opportunities across India, providing employment to millions, especially in marginalized communities. It supports local businesses, contributes to corporate social responsibility initiatives, and promotes a circular economy model. Women, in particular, benefit from employment opportunities in manufacturing units.